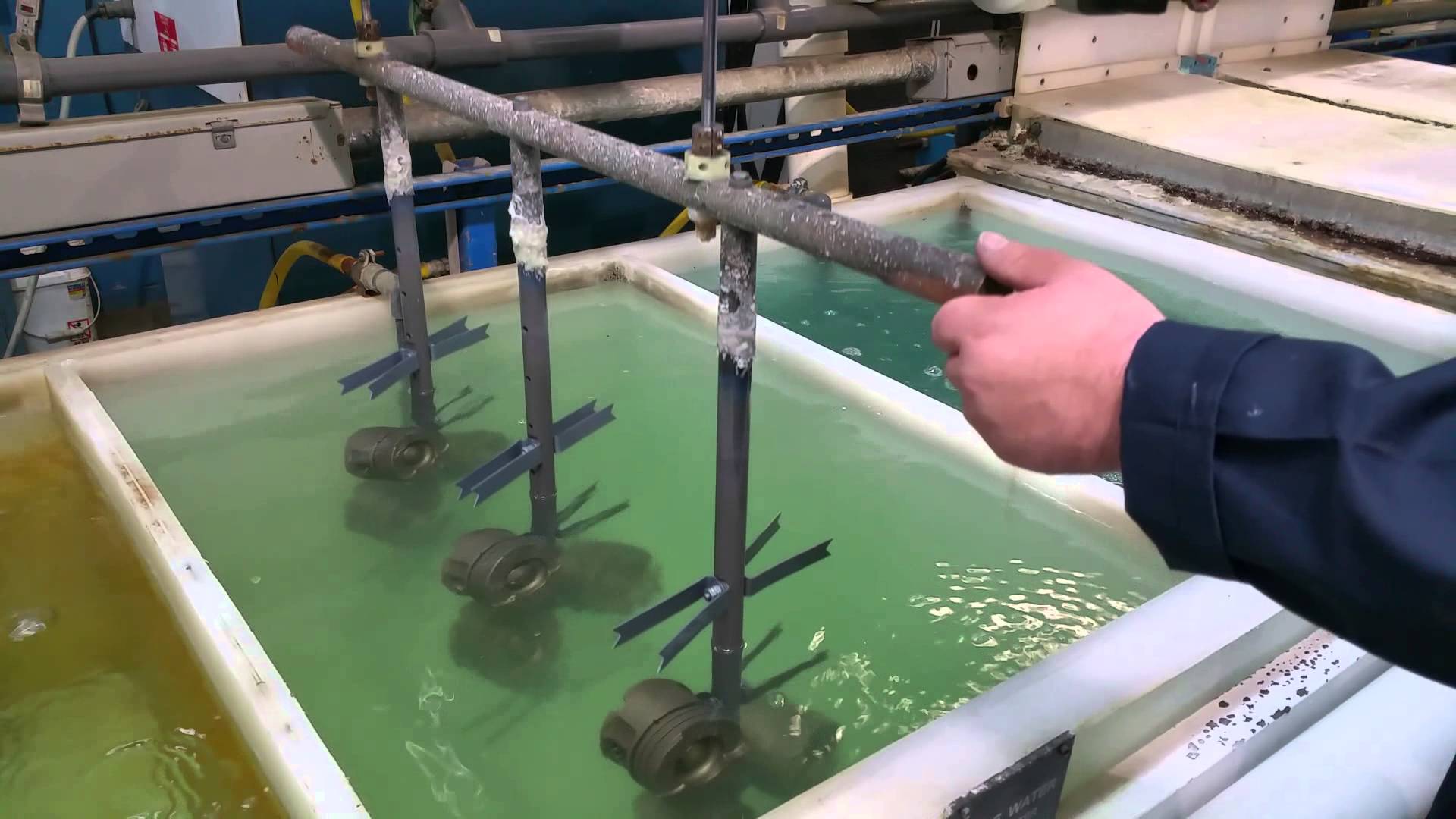

You see it on sports equipment, appliances and many other colored metallic items. Anodizing is a process where metal, typically aluminum, is dipped into an anodizing tank of chemicals, like chromatic or sulfuric acid, and then charged with a jolt of electricity, forming an oxide coating on the surface. Here are a few reasons why you would want to process metals this way.

Easier To Paint

The porous surface of an anodized piece of metal attracts paint and coatings better than a smooth piece of metal. There can be several layers of oxide and it is still an ideal item to add color to. Some of these treated metals can be imprinted with a screen print image instead of paint, giving that particular metal your own personal image.

Recyclable Material

The layers that are added to an anodized piece of metal are made up of the substance itself combined with a chemical wash and electricity. Due to that combination, nearly all of the piece is recyclable other that a few stray trace metals and some of the types of paints used,

Keeping It Together

This type of coating is resistant to corrosion so it will last for years. The layers are thin and durable. It takes a great deal of effort to wear anodize off. Paint and sealants can add even more protection to the aluminum. it makes your item look great while functioning its best.

Affordable To Use

Even though anodized metal is strong and durable, it costs very little to process. The aluminum, zinc, and other metallic substances are simply dipped into the solution. Other coatings, such as powder coatings, take several steps to prepare and finish it. This can be expensive. You can add several anodized layers to metal without accumulating extra cost then follow it up with paint.